Magnetic Particle Inspection (MPI) & DYE Penetrant Inspection (DPI)

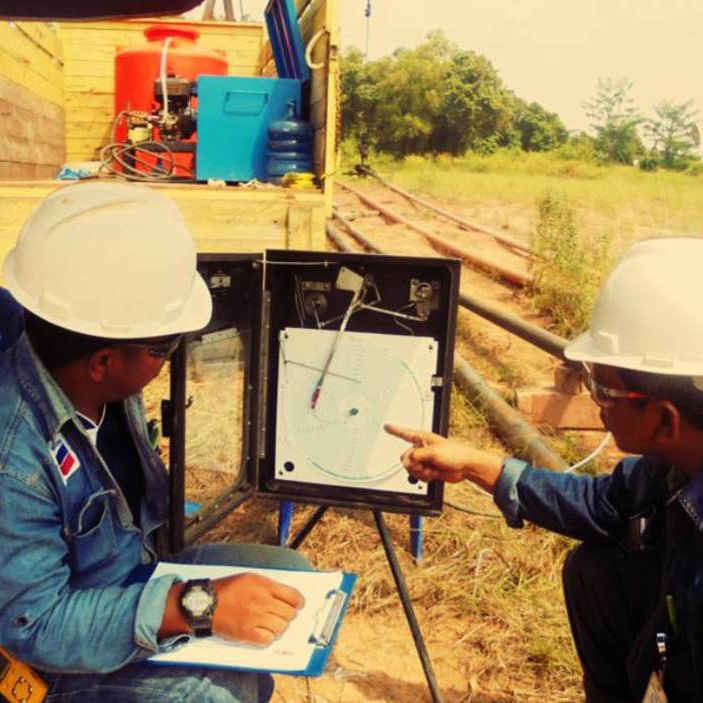

Pressure Safety Valve and PSV Testing Division

The Pressure Safety Valve and PSV Testing Division is responsible for the installation, maintenance, and testing of pressure safety valves (PSVs) on oil and gas rigs. PSVs are critical safety devices that protect personnel and equipment from overpressure events. The division's work ensures that PSVs are functioning properly and will operate as designed in the event of an emergency.

Ultrasonic Test Phased Array (UT-PA)

Phased array ultrasonic testing (PAUT) is a non-destructive testing (NDT) method that uses sound waves to inspect materials for flaws. PAUT is a relatively new NDT method, but it has quickly become one of the most popular methods due to its many advantages over other NDT methods.

Inspection Engineer and Inspector for QA QC, Rotating, Electrical, Mechanical, Civil, General

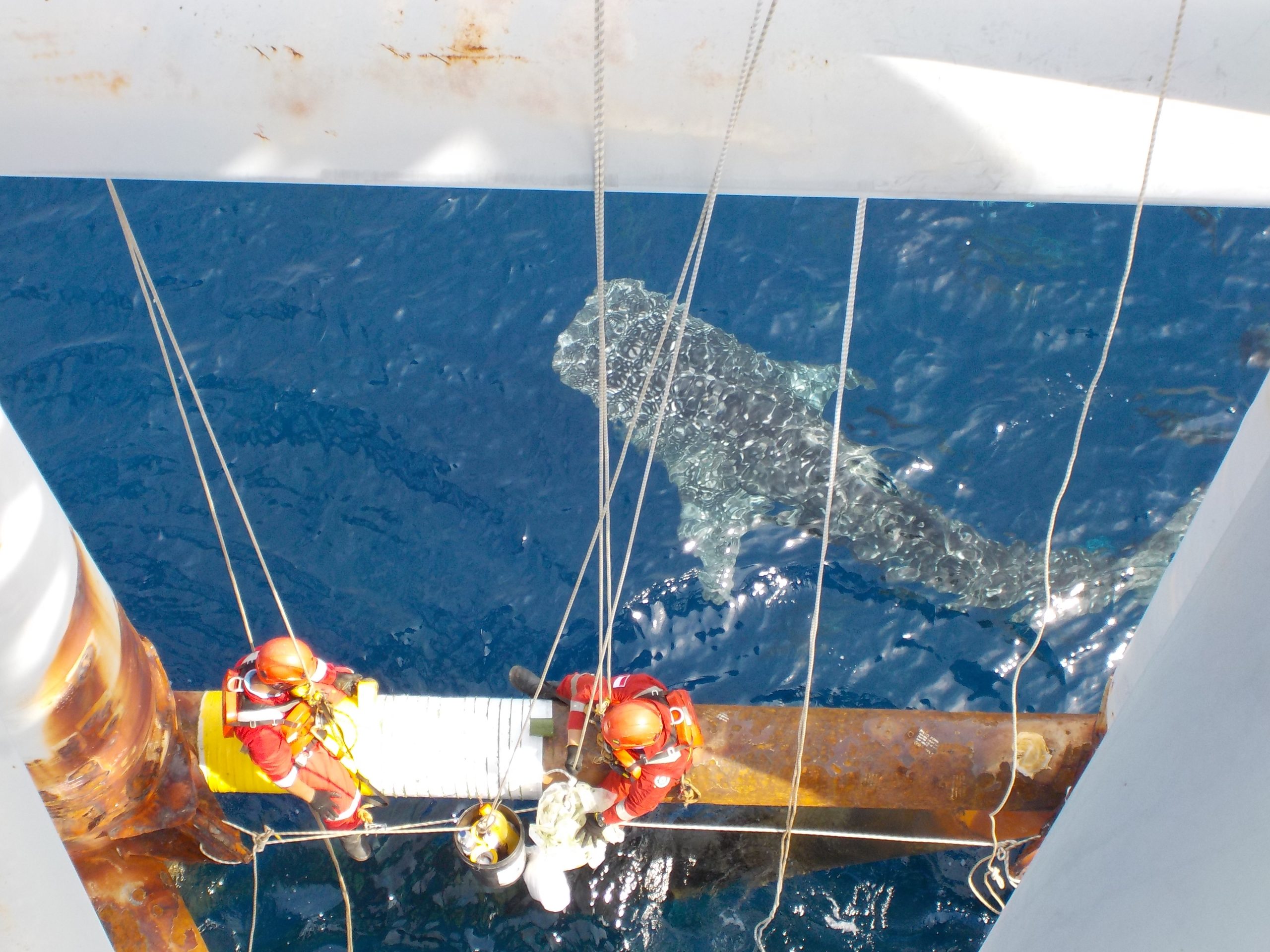

Rope Access Technique (RAT)

Other Technique (Scaffolding)

SMS 12 MONTHLY RIG ANNUAL INSPECTIONS SERVICES

SMS 6 MONTHLY RIG ANNUAL INSPECTIONS SERVICES