PT. Spektra Megah Semesta is a trusted partner in Hydrostatic Testing (Hydrotest) and Commissioning Tests for pipelines, pressure vessels, and industrial equipment. Based in Indonesia, we provide reliable and certified solutions that comply with MIGAS, LEEA, and SNI standards. Our experienced engineers and technicians ensure every system is thoroughly tested for safety, pressure integrity, and operational readiness, giving you confidence for a smooth and secure start-up.

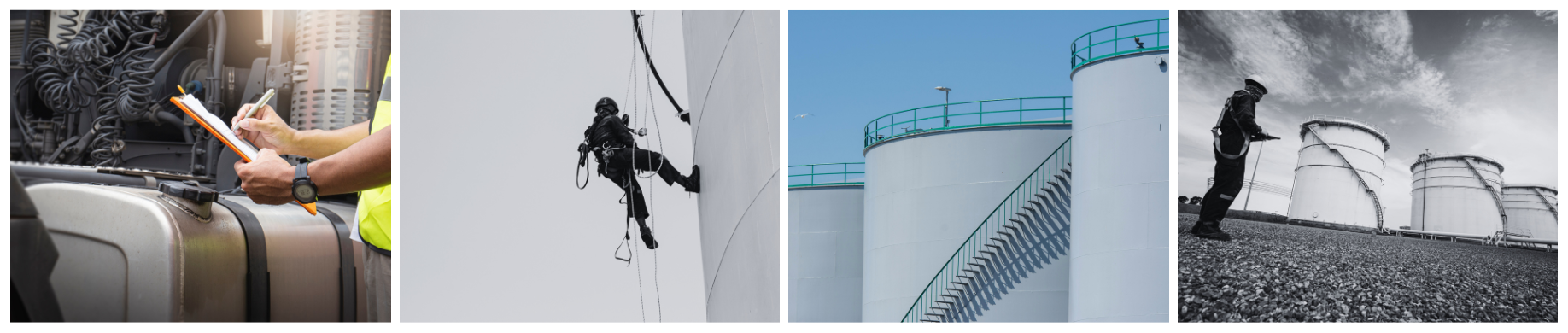

In addition to Pre-Commissioning, our expertise extends to API-certified inspections that safeguard the long-term performance and compliance of your assets:

▶︎API 570 – Piping Inspections

We inspect piping systems to detect corrosion, leaks, or mechanical issues, ensuring pipelines maintain structural integrity and operational safety throughout their lifecycle.

▶︎API 510 – Pressure Vessel Inspections

Our certified inspections evaluate the condition and reliability of pressure vessels, identifying risks before they escalate into costly downtime or safety hazards.

▶︎API 653 – Tank Inspections

From storage tanks to critical containment systems, we conduct detailed API 653 inspections to assess corrosion, settlement, and welding quality, ensuring tanks remain safe and compliant.

▶︎API 4G – Derrick Mast Inspections

We provide comprehensive structural inspections for derrick masts, focusing on stability, load-bearing capacity, and safety compliance in drilling operations.

▶︎API 2C / 2D – Crane Inspection, Repair & Maintenance (IRM)

Our crane inspection and maintenance services follow API 2C/2D standards, covering offshore and onshore lifting equipment. We ensure cranes operate at peak performance while minimizing risks of mechanical failure.

By combining Pre-Commissioning Services with API-certified inspections, PT. Spektra Megah Semesta delivers end-to-end assurance—from system start-up to long-term asset reliability—helping clients achieve safe, efficient, and compliant operations. Select the pre-commissioning service below for detailed information:

As part of our Pre-Commissioning scope, we provide a full range of Pressure Testing services to verify the strength, durability, and leak-tightness of industrial systems before they are placed into service:

-

▶︎Hydro Test (Hydrostatic Test)

Using water as the test medium, hydro testing is the most common method to validate the integrity of pipelines, vessels, and equipment under pressure. This test confirms structural soundness and identifies potential leaks or weaknesses before commissioning.

▶︎Pneumatic Test

When water is not suitable, pneumatic testing with air, nitrogen, or another inert gas is applied. This method is highly sensitive in detecting small leaks, ensuring the system is airtight and safe for operation.

▶︎Hydraulic Test

Hydraulic testing applies fluid pressure (often oil or water) to assess equipment performance under operating conditions. It ensures systems can safely withstand the pressure levels required during real operations.

By integrating Hydro, Pneumatic, and Hydraulic tests into our Pre-Commissioning Services, PT. Spektra Megah Semesta provides clients with complete assurance of system safety, compliance, and readiness—reducing risks and enabling a smooth transition to full operation.

Precise tightening and torque control to ensure leak-free and secure flange connections.

Removal of contaminants from lubrication and hydraulic systems to maintain equipment reliability.

Application of protective coatings to prevent corrosion and extend the lifespan of flange joints.

Professional use of hydraulic tensioners for accurate bolt loading, ensuring system integrity under pressure.

Verification that mechanical and electrical systems perform according to design and operational requirements.

Mechanical and chemical cleaning methods to remove debris, deposits, and impurities from process systems.

High-pressure water jetting to clean surfaces, pipelines, and equipment with precision and efficiency.

Pipeline pigging operations to clean, inspect, and maintain optimal flow efficiency.

Circulation of fluids at high velocity to remove debris and contaminants, ensuring clean and safe pipelines.

Compressed air or nitrogen blowing to clear pipelines and systems of foreign particles before commissioning.

By integrating these services, PT. Spektra Megah Semesta ensures that every system is fully optimized, free from contamination, and ready for safe operation from day one. Our proven methods minimize risks, reduce downtime, and provide clients with complete confidence in their critical assets.