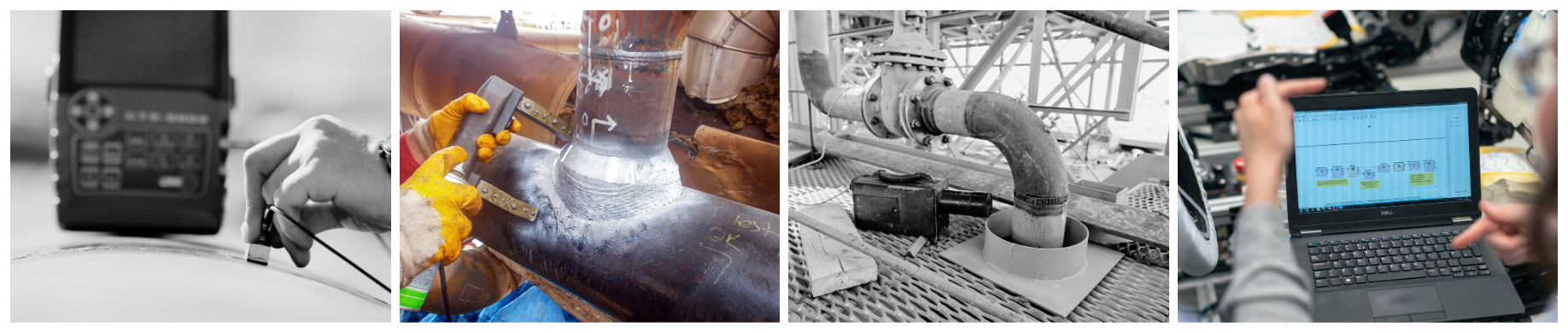

Welcome to PT Spektra Megah Semesta – Your Trusted Partner in Non-Destructive Testing (NDT) Excellence.

At PT Spektra Megah Semesta, we deliver trusted Non-Destructive Testing (NDT) solutions across Indonesia to ensure the integrity and reliability of your critical assets. From conventional methods such as Ultrasonic Testing (UT), Radiographic Testing (RT), and Magnetic Particle Testing (MT), to advanced technologies like Phased Array Ultrasonic Testing (PAUT), Time of Flight Diffraction (TOFD), and Eddy Current Testing (ECT), our expertise covers a full spectrum of inspection needs.

With certified professionals, cutting-edge equipment, and strict adherence to safety and quality standards, PT Spektra Megah Semesta provides accurate, efficient, and dependable results for industries including oil and gas, energy, marine, and manufacturing. Select the NDT service below for detailed information:

Ultrasonic Testing (UT) is one of the core inspection services offered by PT Spektra Megah Semesta. As a highly versatile method, UT utilizes advanced electronic equipment to evaluate materials capable of transmitting mechanical vibrations. This technique effectively detects both linear and non-linear flaws while also providing three-dimensional interpretation of internal structures.

In practice, the UT instrument generates electrical pulses that are transformed into ultrasonic waves. These waves travel through the material and reflect back when encountering irregularities or defects caused by differences in acoustic properties. The returning signals are then reconverted into electrical energy and displayed on a monitor, where their position and amplitude accurately indicate the location and size of any flaws.

With a team of certified experts and state-of-the-art technology, PT Spektra Megah Semesta ensures that every Ultrasonic Testing service delivers precise, reliable, and efficient results—helping industries maintain the integrity, safety, and performance of their critical assets.

▶︎Time-of-Flight Diffraction (TOFD) Units

Advanced ultrasonic equipment that accurately detects and sizes internal cracks and defects for reliable inspections.

▶︎Phased Array Ultrasonic Testing (PAUT) Systems

High-tech ultrasonic systems that provide detailed imaging of materials, detecting surface and subsurface flaws efficiently.

▶︎Portable Ultrasonic Flaw Detectors

Compact, field-ready devices for on-site inspection, quickly identifying internal defects in various materials.

PT Spektra Megah Semesta offers reliable Magnetic Particle Testing (MPT) services to detect surface and near-surface defects in ferromagnetic materials such as iron, nickel, and cobalt. By applying a magnetic field and magnetic particles, even the smallest cracks or discontinuities become visible, ensuring safety and quality in critical components. Within MPT, the following tools and processes are commonly used:

▶︎Portable Magnetic Particle Inspection Kit

PT Spektra Megah Semesta utilizes portable inspection kits for on-site testing, enabling fast and efficient inspections wherever clients need them.

▶︎Magnetic Particle Inspection

Our inspection process ensures accurate detection of cracks, seams, or inclusions, supporting industries such as automotive, aerospace, energy, and manufacturing in maintaining high reliability standards.

▶︎Electromagnetic Yokes

With advanced electromagnetic yokes, PT Spektra Megah Semesta delivers precise, localized inspections to detect weld defects and surface cracks effectively, whether in workshops or field operations.

PT Spektra Megah Semesta provides reliable Dye Penetrant Testing (DPT) services to detect surface-breaking defects such as cracks, porosity, or seams in non-porous materials including metals, plastics, and ceramics. This simple yet highly effective method ensures that even the smallest flaws are revealed, helping industries maintain safety, quality, and performance. Within DPT, the following tools and equipment are commonly used:

▶︎Portable Penetrant Inspection Kit

PT Spektra Megah Semesta utilizes portable DPT kits for on-site inspections, enabling fast, flexible, and efficient testing in the field—ideal for maintenance checks and remote operations.

▶︎Dye Penetrant Inspection Stations

For workshop and laboratory inspections, PT Spektra Megah Semesta operates fixed penetrant stations that provide controlled environments for applying penetrants, cleaning, and developing. This ensures accurate, consistent, and repeatable results.

▶︎Inspection Bath and Spray Units

With specialized bath and spray units, PT Spektra Megah Semesta guarantees complete coverage of penetrant and developer fluids, ensuring thorough detection of flaws even in high-volume testing or complex-shaped components.

PT Spektra Megah Semesta offers advanced Eddy Current Testing (ECT) solutions to detect surface and near-surface defects in conductive materials. This non-destructive method works by inducing electrical currents (eddy currents) into the material and analyzing their response to reveal cracks, corrosion, or other irregularities. ECT is highly valued for its speed, sensitivity, and ability to inspect without removing coatings or causing damage to the component. The types of equipment/tools used in Eddy Current Testing (ECT):

▶︎Portable Eddy Current Flaw Detectors

PT Spektra Megah Semesta employs portable flaw detectors that provide rapid, accurate, and on-site inspections. These compact devices are ideal for maintenance, field operations, and quick evaluations of conductive materials.

▶︎Eddy Current Array Systems

With state-of-the-art array systems, PT Spektra Megah Semesta delivers faster and more detailed inspections by covering larger areas in a single scan. This technology enhances efficiency while providing high-resolution imaging of defects.

▶︎Eddy Current Testing Probes

PT Spektra Megah Semesta uses a wide range of specialized probes to suit different inspection needs, from surface crack detection to conductivity measurements. These probes ensure versatility and precision in various industrial applications.

PT Spektra Megah Semesta provides Borescope and Endoscope inspection services to support precise visual examinations of internal areas that are otherwise inaccessible. These advanced optical tools allow industries to inspect turbines, pipelines, engines, welds, and other confined spaces without dismantling equipment—saving both time and cost while ensuring operational safety and reliability.

-

▶︎Flexible Borescopes

PT Spektra Megah Semesta uses flexible borescopes equipped with fiber optic technology that can bend and maneuver through complex or curved pathways. This makes them ideal for inspecting pipelines, internal engine parts, or any area with limited accessibility. -

▶︎Video Borescopes

With state-of-the-art video borescopes, PT Spektra Megah Semesta delivers high-resolution, real-time imaging of internal structures. These devices allow for detailed visual inspection, digital recording, and documentation—providing clients with clear evidence of any defects or irregularities.

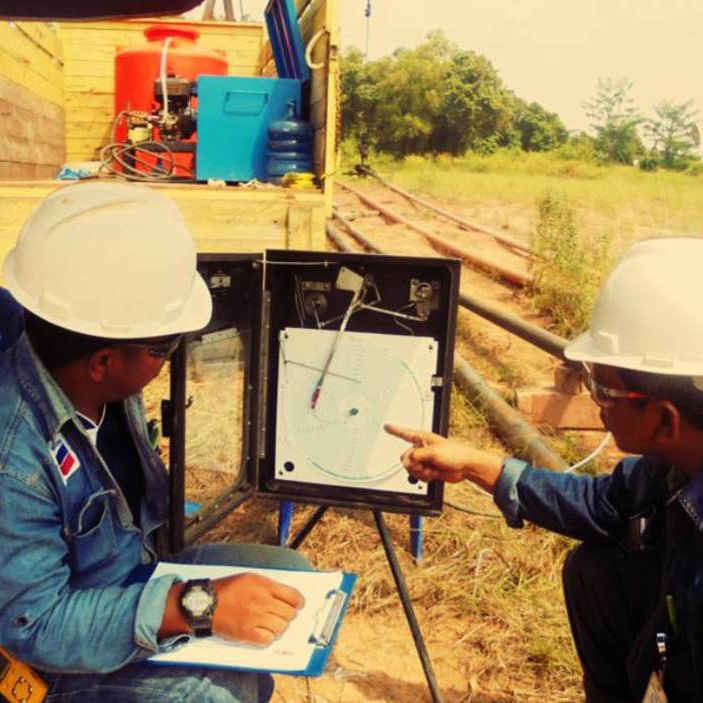

PT Spektra Megah Semesta provides advanced Leak Testing solutions to identify and measure leaks in pressurized systems, pipelines, tanks, and other critical components. Leak testing ensures safety, efficiency, and compliance with industry standards by detecting even the smallest leaks that could compromise system performance or create hazards.

-

▶︎Helium Leak Detectors

PT Spektra Megah Semesta utilizes highly sensitive helium leak detectors capable of identifying extremely small leaks with precision. This method is ideal for industries that demand the highest reliability, such as aerospace, energy, and pharmaceuticals. -

▶︎Bubble Leak Testing Kits

For a simple and cost-effective solution, PT Spektra Megah Semesta offers bubble leak testing kits. By applying a soap solution or bubble-forming liquid over the test area, leaks can be quickly identified by the formation of bubbles—making this method useful for field inspections and routine maintenance. -

▶︎Vacuum Leak Testing Systems

With vacuum systems, PT Spektra Megah Semesta provides an efficient method of detecting leaks by creating a pressure differential and monitoring the response. This approach is widely used for tanks, sealed vessels, and other large equipment where accuracy and reliability are critical.

PT Spektra Megah Semesta delivers reliable Visual Testing (VT) services as a fundamental non-destructive inspection method to evaluate the surface condition of components, structures, and equipment. By using advanced visual inspection tools, PT Spektra Megah Semesta ensures early detection of defects such as cracks, corrosion, misalignments, or weld irregularities—helping clients maintain safety, compliance, and operational efficiency.

-

▶︎Borescopes and Endoscopes

PT Spektra Megah Semesta employs high-quality borescopes and endoscopes to access and visually inspect confined or hard-to-reach areas without dismantling equipment. These tools provide clear imaging of internal surfaces, enabling fast and accurate assessments of component conditions. -

▶︎Remote Visual Inspection (RVI) System

With state-of-the-art RVI systems, PT Spektra Megah Semesta offers real-time, high-resolution imaging for inspections in hazardous or inaccessible environments. These systems enhance inspection accuracy while improving safety by reducing the need for direct human entry.

PT Spektra Megah Semesta provides Magnetic Flux Leakage (MFL) testing to detect surface and near-surface defects that are often difficult to identify with conventional Radiographic Testing (RT) or Ultrasonic Testing (UT). Unlike UT, which has a dead zone near the surface, MFL effectively reveals flaws such as corrosion, pitting, and cracks by measuring distortions in the magnetic field.

With this advanced method, PT Spektra Megah Semesta helps industries ensure the integrity of pipelines, storage tanks, and other steel structures—delivering accurate, efficient, and reliable inspection results.